Sizing Pump or Pumping Station

What is a sewage pumping station?

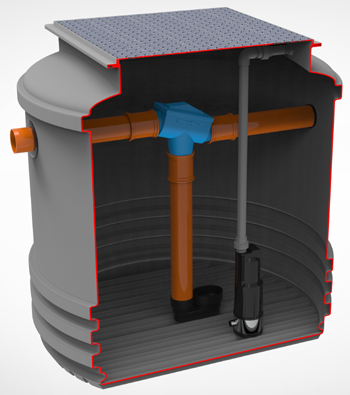

Sewage pumping stations are typically chambers with automatic pumps inside to move water from a lower elevation a higher mains drainage system when gravity flow is not an option.

What is a sump pump?

Sump pumps are typically chambers with automatic pumps inside to move water usually from the celler where water can enter the property and pump it up to the mains drainage.

Simple Calculation

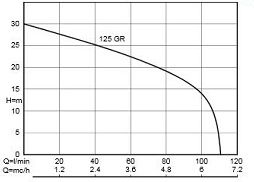

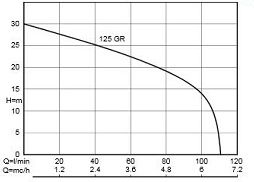

All pumps works best at the centre of the pump curve (see the pumps technical specification pump curves). How to work this out based on a 5m lift pump.

A 5m lift means the pumps maximum lift is 5m (this is the maximum height the pump will lift). To work out your "total dynamic lift" you need to take the overall lift (from pump to highest point of run) and the overall distance.

To calculate - Take the overall lift and then for every 10m horizontal add another 0.5m to the lift.

e.g: you have a run of 30m with a lift of 1.5m, this equates to 3.0m overall dynamic lift. Then look at the pump curve at 3m lift and see the flow. see the pump curve chart example below.

If your overall lift surpasses the 5m, you need to move up to a higher head pump.

Also note: Many people make the mistake of over-specifying a pump. eg: buying a 15m lift pump to do the job of a 5m lift pump and assume the power will prolong the life of the pump. Wrong! Too much lift puts tremendous back pressure on the pump and it will quickly burn out.

Typical Pump Curve

Guide To Sizing A System

1. Determine the application the pump is required to do: sump, effluent or sewage.

2. Determine voltage of electrical supply for pump.

3. Determine the approx GPM of flow into system using velocity load, velocity is determined with a minimum of 2ft per second flow in order to keep pipeline free. The following is recommended for use.

pipe size 1.5" - 13GPM

pipe size 2" - 21GPM

System Load Sizing (as a general rule)

Sump systems: Caculate basement square footage, divide by 100 and then multiplied by 2.50 will equate the GPM (i.e 500 sq.ft basement will equate to 12.5 GPM)

Sewage systems You must add total fixtures (e.g taps, w/c, bath, shower, washine machine etc) that will drain to the system. Each unit has a value (see table below)

Add all fixtures values together and multiply by 0.5 to get an estimated GPM load (e.g 45 fixtures x 0.5 = 22.5 GPM). The GPM rate needs to be greater than the required velocity in order to keep the pipe free of debris.

Value table

Bath = 2

Dishwasher = 2

Kitchen Sink = 2

W/C = 2

Shower = 2

Unlisted 1.5" pipe = +3

Unlisted 2" pipe = +4

Average flow rate for 3/4 bedroom property is approx 10-12GPM

Estimates vary, but each person uses about 80-100ltr of water per day.

Duty stand-by

typically duty stand-by (or 24hr stoarge) for a sewage pumping station for a 24hr use property is 150ltr per person per day. (for the residential property you do this by bedrooms but doubling up the 1st bedroom)

A 4 bedroom house is classed as 5 people (first room is always classed as 2 people) requiring 150ltr per day per person, you need a minimum of 750ltr chamber for duty stand-by.

for offices, classrooms etc (buildings only used by day, this is reduced to 50ltr per person per day. ie an office with 30 people in total would need 1,500ltr

For visitors storage is 5ltr per person

(Example: a restaurant with 8 staff and 100 visitors per day would require 8 x 50ltr and 100 x 5ltr = 900ltr storage)

(note: if other parts of your property can get into the mains drains, then storage for your pumping station becomes void and now just becomes enough to accommodate soil pipe depth and size of pump)

Soil pipe falls;

Typically:- Building Regs Part H give 'gradient limits' of 18-90mm per 1m length for soil pipes and 18-44mm for 40mm sink etc waste pipes

Midway point is generally the standard.

Gallons per Miniute: Amount of liquid flow in a system - Not how fast it is moving through a pipe.

Velocity: Speed of flow through a pipe system - Not how much is moving through the pipe

Minimum Velocity: (Scouring Velocity) 2 feet per second is required to keep solids suspended or from settling inside the pipe.

Maximum Velocity: Velocity greater than 10 feet per second will damage piping systems, valves, etc.

Static Head: Total distance in elevation from the low water line (Off float level) inside the basin to the point of discharge (Vertical distance)

Friction Loss: Any additional head created by the resistance within the piping system due to pipe length, fittings and flow rate.

Sewer Back Pressure: (1 PSI = 2.31 feet of head) Due to multiple pump systems...i.e. pumping into a grinder loop or the bottom of manhole.

Total Dynamic Head: Static Head (constant) + Developed Head (changes in flow rate) = TDH

Shut Off Head: The point at which the pump will no longer provide any flow. This is shown as the furthest point on the left hand side of the pumps performance curve.

Types of Pump

Sump Pump: pump to handle water that does not drain by gravity. ie. basement sumps, car parks, rainwater harvesting, manholes and low land areas.

Effluent Pump: pump for grey, soiled water, ie from septic tanks. up to 3/4" inch.

Sewage Pump: pump to handle waste from homes, offices and anywhere with W/C facilities. They are not grinder pumps and should not be used for commercial applications. will not handle sanitary products and products inc nappies, napkins etc.

Pump Sizing

Pump Lift: The vertical lift (dynamic head) it has to pump. measured from the outet of the pump to its highest pumping within the discharge pipe.

Horizontal Run: distance slows down the liquid within the pump and horizontal run needs to be considered when calculating the overall pump performance.

Pipe Size: The pump discharge size will determine the pipe size. Using pipe that is smaller than the pump discharge will cause friction loss and more back pressure on the pump affecting its performance.

GPM: (Gallons Per Minute) Determine how many gallons per minute the pump needs to remove. undersizing the pumps basin will cause the pump to run more frequent affecting the lifespan of the pump.

This is a general guide as to what type of pumping station you should be looking for, but may not be the correct pumping station for your specific job.

Please note, variants of pump power and chamber size can be built to your specific requirements. Please call, we'll be more than happy to help choose the right kit.

So as a general rule;

Cellars (no toilet)

Sump pump for cold storage type cellar

Sump pump for cellar conversion (living space)

Cellar conversion (with toilet) garden room conversion, garage conversion, extensions

Annex's or deep invert level systems

Full house up to 4-5 beds

Small commercial, offices, pubs, construction sites, etc

Larger commercial and multiple properties

Garden surface water, car parks, general land drain

General things to consider when selecting the right pumping stations

1. Building regs (see pumping station sizing guide)

2. Depth of invert

3. Overall pump lift

4. Overall pump distance

5. Pump flow (at final discharge point)

6. Chamber storage capacity

Options for pumping stations; (what we can offer)

1. High water alarms

2. Dual pumps

3. Higher lift pumps

4. Manhole cover type

5. Rigid or flexi discharge pipe

6. Sewer connection kit

7. Control panel kiosks

8. SMS texting system

9. Commissioning

10. Servicing

Sewage pumping stations are typically chambers with automatic pumps inside to move water from a lower elevation a higher mains drainage system when gravity flow is not an option.

What is a sump pump?

Sump pumps are typically chambers with automatic pumps inside to move water usually from the celler where water can enter the property and pump it up to the mains drainage.

Simple Calculation

All pumps works best at the centre of the pump curve (see the pumps technical specification pump curves). How to work this out based on a 5m lift pump.

A 5m lift means the pumps maximum lift is 5m (this is the maximum height the pump will lift). To work out your "total dynamic lift" you need to take the overall lift (from pump to highest point of run) and the overall distance.

To calculate - Take the overall lift and then for every 10m horizontal add another 0.5m to the lift.

e.g: you have a run of 30m with a lift of 1.5m, this equates to 3.0m overall dynamic lift. Then look at the pump curve at 3m lift and see the flow. see the pump curve chart example below.

If your overall lift surpasses the 5m, you need to move up to a higher head pump.

Also note: Many people make the mistake of over-specifying a pump. eg: buying a 15m lift pump to do the job of a 5m lift pump and assume the power will prolong the life of the pump. Wrong! Too much lift puts tremendous back pressure on the pump and it will quickly burn out.

Typical Pump Curve

Guide To Sizing A System

1. Determine the application the pump is required to do: sump, effluent or sewage.

2. Determine voltage of electrical supply for pump.

3. Determine the approx GPM of flow into system using velocity load, velocity is determined with a minimum of 2ft per second flow in order to keep pipeline free. The following is recommended for use.

pipe size 1.5" - 13GPM

pipe size 2" - 21GPM

System Load Sizing (as a general rule)

Sump systems: Caculate basement square footage, divide by 100 and then multiplied by 2.50 will equate the GPM (i.e 500 sq.ft basement will equate to 12.5 GPM)

Sewage systems You must add total fixtures (e.g taps, w/c, bath, shower, washine machine etc) that will drain to the system. Each unit has a value (see table below)

Add all fixtures values together and multiply by 0.5 to get an estimated GPM load (e.g 45 fixtures x 0.5 = 22.5 GPM). The GPM rate needs to be greater than the required velocity in order to keep the pipe free of debris.

Value table

Bath = 2

Dishwasher = 2

Kitchen Sink = 2

W/C = 2

Shower = 2

Unlisted 1.5" pipe = +3

Unlisted 2" pipe = +4

Average flow rate for 3/4 bedroom property is approx 10-12GPM

Estimates vary, but each person uses about 80-100ltr of water per day.

Duty stand-by

typically duty stand-by (or 24hr stoarge) for a sewage pumping station for a 24hr use property is 150ltr per person per day. (for the residential property you do this by bedrooms but doubling up the 1st bedroom)

A 4 bedroom house is classed as 5 people (first room is always classed as 2 people) requiring 150ltr per day per person, you need a minimum of 750ltr chamber for duty stand-by.

for offices, classrooms etc (buildings only used by day, this is reduced to 50ltr per person per day. ie an office with 30 people in total would need 1,500ltr

For visitors storage is 5ltr per person

(Example: a restaurant with 8 staff and 100 visitors per day would require 8 x 50ltr and 100 x 5ltr = 900ltr storage)

(note: if other parts of your property can get into the mains drains, then storage for your pumping station becomes void and now just becomes enough to accommodate soil pipe depth and size of pump)

Soil pipe falls;

Typically:- Building Regs Part H give 'gradient limits' of 18-90mm per 1m length for soil pipes and 18-44mm for 40mm sink etc waste pipes

Midway point is generally the standard.

Gallons per Miniute: Amount of liquid flow in a system - Not how fast it is moving through a pipe.

Velocity: Speed of flow through a pipe system - Not how much is moving through the pipe

Minimum Velocity: (Scouring Velocity) 2 feet per second is required to keep solids suspended or from settling inside the pipe.

Maximum Velocity: Velocity greater than 10 feet per second will damage piping systems, valves, etc.

Static Head: Total distance in elevation from the low water line (Off float level) inside the basin to the point of discharge (Vertical distance)

Friction Loss: Any additional head created by the resistance within the piping system due to pipe length, fittings and flow rate.

Sewer Back Pressure: (1 PSI = 2.31 feet of head) Due to multiple pump systems...i.e. pumping into a grinder loop or the bottom of manhole.

Total Dynamic Head: Static Head (constant) + Developed Head (changes in flow rate) = TDH

Shut Off Head: The point at which the pump will no longer provide any flow. This is shown as the furthest point on the left hand side of the pumps performance curve.

Types of Pump

Sump Pump: pump to handle water that does not drain by gravity. ie. basement sumps, car parks, rainwater harvesting, manholes and low land areas.

Effluent Pump: pump for grey, soiled water, ie from septic tanks. up to 3/4" inch.

Sewage Pump: pump to handle waste from homes, offices and anywhere with W/C facilities. They are not grinder pumps and should not be used for commercial applications. will not handle sanitary products and products inc nappies, napkins etc.

Pump Sizing

Pump Lift: The vertical lift (dynamic head) it has to pump. measured from the outet of the pump to its highest pumping within the discharge pipe.

Horizontal Run: distance slows down the liquid within the pump and horizontal run needs to be considered when calculating the overall pump performance.

Pipe Size: The pump discharge size will determine the pipe size. Using pipe that is smaller than the pump discharge will cause friction loss and more back pressure on the pump affecting its performance.

GPM: (Gallons Per Minute) Determine how many gallons per minute the pump needs to remove. undersizing the pumps basin will cause the pump to run more frequent affecting the lifespan of the pump.

This is a general guide as to what type of pumping station you should be looking for, but may not be the correct pumping station for your specific job.

Please note, variants of pump power and chamber size can be built to your specific requirements. Please call, we'll be more than happy to help choose the right kit.

So as a general rule;

Cellars (no toilet)

Sump pump for cold storage type cellar

SPD100 single pump system | Z150 Single Zoeller pump system (vertical float) |

Sump pump for cellar conversion (living space)

Cellar conversion (with toilet) garden room conversion, garage conversion, extensions

Mini 190S Sewage Station | Mini Z190 Zoeller Sewage Station |

Annex's or deep invert level systems

Full house up to 4-5 beds

800S Sewage Station | 1000S Sewage Station |

Small commercial, offices, pubs, construction sites, etc

Larger commercial and multiple properties

M3500s Macerator Pumping Station | M3500 Dual Macerator Pumping Station |

Garden surface water, car parks, general land drain

General things to consider when selecting the right pumping stations

1. Building regs (see pumping station sizing guide)

2. Depth of invert

3. Overall pump lift

4. Overall pump distance

5. Pump flow (at final discharge point)

6. Chamber storage capacity

Options for pumping stations; (what we can offer)

1. High water alarms

2. Dual pumps

3. Higher lift pumps

4. Manhole cover type

5. Rigid or flexi discharge pipe

6. Sewer connection kit

7. Control panel kiosks

8. SMS texting system

9. Commissioning

10. Servicing